PVS Installation Guidelines

- Dig trenches in accordance to plans and specifications; confirm the location of any existing utility lines or piping.

- Allow 3 inches of encasement clearance around pipe for backfill of drainage material or concrete. Structural reinforcement or a slab must be in place where point loading may occur.

- Pitch all piping systems back towards the utility room for proper drainage. A vapor barrier is recommended for areas with high water tables or poor drainage.

- Hold-down straps and pipe reinforcements are recommended for large diameter or concrete encased systems.

- Fasten joints with metal screws or pop rivets used at 6" intervals with a minimum of three per joint, then sealed by sealer or tape.

- PVC paint is available to touch up any scratches that may have occurred during installation.

- Care should be taken to not pour or back-fill directly unto the piping systems. The pour or back-fill can now be completed, with care being used as the concrete or back-fill is placed over the top of the duct, no powered vibrator should be used in compaction of the concrete or back-fill. For soil encasement systems, no external loads should be allowed at any time unless previous calculations allow for these load conditions.

|

Please check your local building codes for more specific installation instructions. |

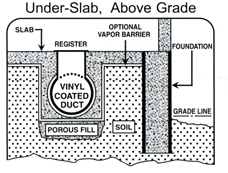

The duct, encased either in concrete or buried directly below a concrete slab, is installed above the original line of undisturbed soil and above the water table. Encasing the duct in concrete with porous fill beneath is the best way to install Marstan vinyl-coated duct. An optional vapor barrier can be placed between the pipe and the fill.

|

The process of PVC sheet mfg. Begins with (1) prime, hot dipped G-60 galv. Steel cleaned & fire treated. (2) A special epoxy primer bonded to both sides of the metal. Finally (3) a 4-mil polyvinyl coating heat fused to one side (4 x 1 Standard) or both sides (4 x 4). |

|

PVS Information

Marstan PVS spiral pipe is UL listed and manufactured from prime hot dipped galvanized steel coated with polyvinyl chloride material, with an outside thickness of 4-mil and inside 1-mil, standard. This is reversible for special purposes. For extreme duty applications a 4x4 coating is applied. External corrugations are standard for 14" diameters and over for underground applications. Standard gauges are 4" to 16" /24 gauge, 17" to 24" /22 gauge, 26" to 48" / 20 gauge. Our PVS coated class I duct has a temperature range of -40 F to 250 F and should not exceed 3600 fpm with positive and negative pressure limits not in excess of 6 inches water column. For more detailed specifications, click here.

PVS Compliance data PVS Compliance data

Marstan PVS products comply with the following codes and industry standards:

UL 181 Class 1

International Mechanical Code - 1996 Section 603

BOCA National Mechanical Code - 1993

ICBO Uniform Mechanical Code - (UMC) 1997

SMACNA Sheet Metal Air Conditioning Contractors National Association

|